JTXG-H

The motor system is applied with industrial series wound carbon brush motor, the enameled wires in the motor with heat resistance up to 180℃ winch is good at heavy duty works;Twin brake system: unique mechanical ratchet gear brake and resistor brake. When power failure or breakdown occurs, brake system is immediately started up for safety purposes;

Based on direct control system, simplify wirings. Low breakdown rate, safe and stable, easy to main & maintain. Equipped with miniature circular connector which is convenient and compact;

Chain is genuine imported from Japan FEC company which is manufactured by this reputed manufacturer in this field worldwide, chain is made of alloy steel material with 80 grade and with four times safety factor;

Equipped with most reliable, efficient, durable planetary reduction gear train. The planetary gear train contains a pair of idler gear made by alloy steel with heat treatment, provides both strength and smooth operation with good resistance to torque loads. Oil bath gear box to prevent overheat from brake device;

High strength steel plate to support the frame of hoist. Applied with electric coating with good rust resistance, good for operation under badly environment when temperature is from minus 10 degree Celsius to plus 40 degrees Celsius;

Motor and gear housings are made of aluminum alloy formed by die-casting with high tenacity and machined by computerized CNC lathe; high precision in assembly, low noise during operation. High grade powder coating on hoist housings provides elegant looking. Ingress protection rating: Ip54, and with waterproof cover as an option for outdoor usage;

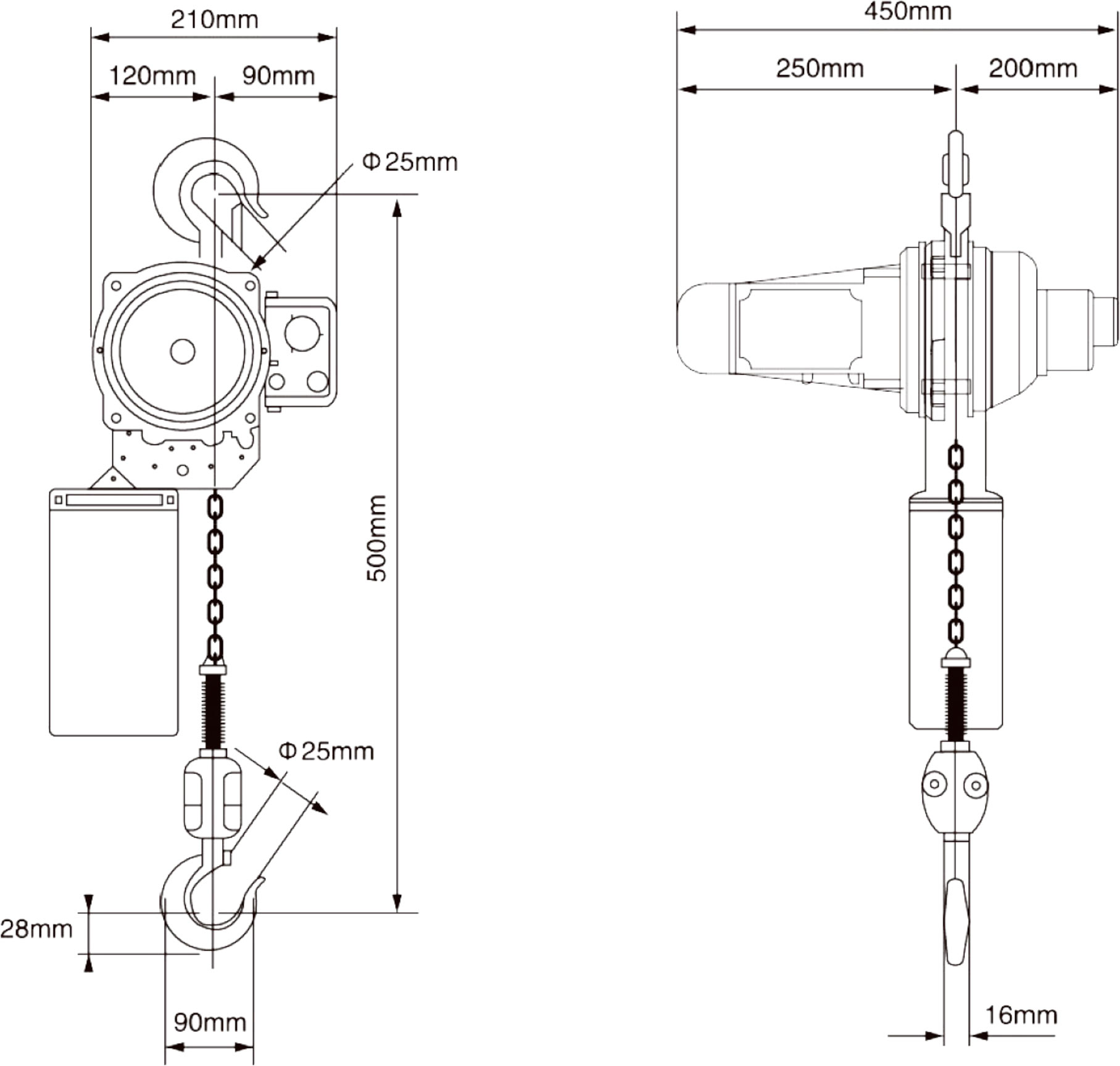

Upper & lower hook unit is made of alloy steel material by die-casting formation, with high strength and four times safety factor. The lower hook is also with safety latch to ensure safety of lifting operations;

Mechanical overload clutch provides protection against overloading and over tight revolving.